The Art and Science of Blending: Custom Solutions for Perfect Mixing

Blending is a fundamental process across a vast range of industries. From the precise formulation of pharmaceuticals to the consistent flavor profiles of food and beverage, the ability to effectively combine ingredients is critical to product quality, consistency, and overall success. A well-designed blending system is the heart of this process, and choosing the right one can make all the difference.

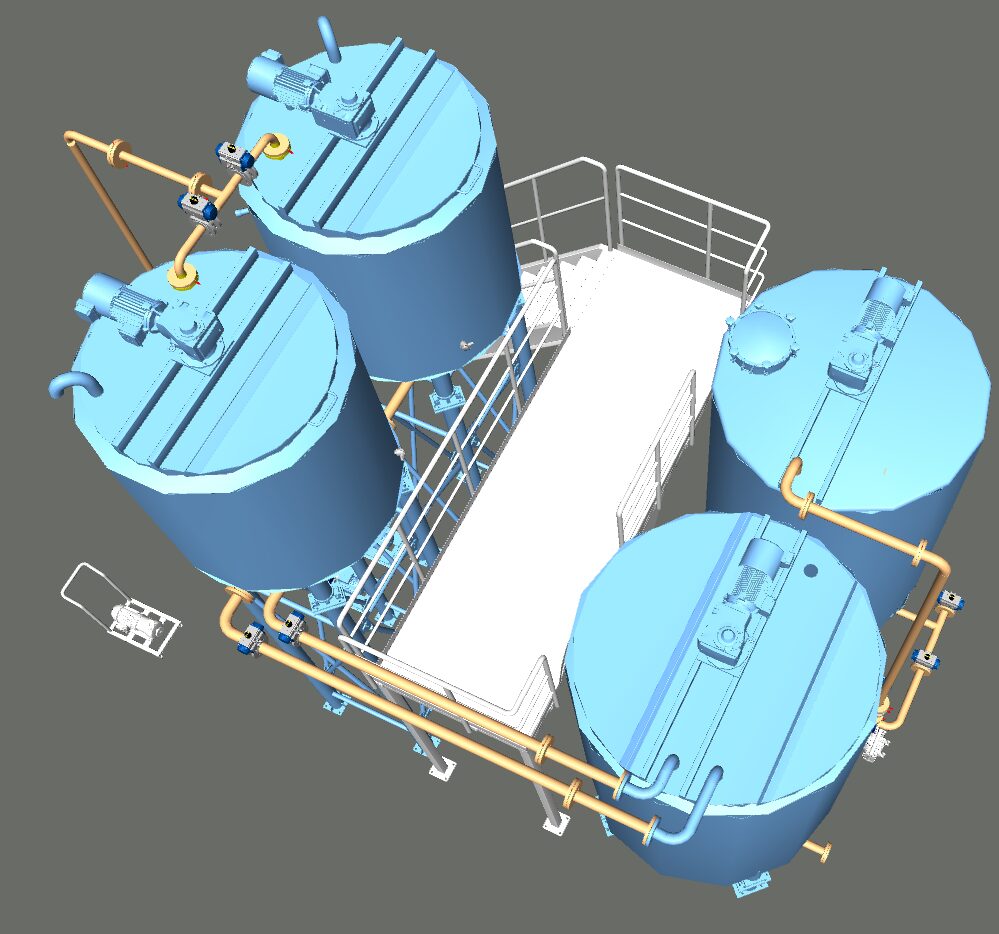

Cedarstone Industry understands that a one-size-fits-all approach simply doesn’t work when it comes to blending. That’s why they specialize in tailored industrial blending solutions, crafting custom-built systems to meet the unique demands of diverse industries. Their expertise lies in understanding the specific challenges and requirements of each application, ensuring perfect mixing every time.

Why a Custom Blending System?

Off-the-shelf blending systems can often fall short. They may not be optimized for the specific viscosity, volume, or chemical properties of the materials being blended. This can lead to:

- Inconsistent Product Quality: Inadequate mixing can result in variations in the final product, affecting taste, texture, potency, or other critical attributes.

- Increased Waste: Poor blending can lead to unusable batches, resulting in wasted materials and lost profits.

- Inefficient Processing: Systems that are not properly designed can consume excessive energy and require more time to achieve the desired blend.

- Maintenance Issues: Mismatched equipment can be prone to breakdowns and require frequent repairs.

Cedarstone’s custom approach eliminates these risks. They work closely with clients to analyze their specific needs and design a blending system that is perfectly suited to their application. This includes selecting the right tank size and configuration, impeller type, motor power, and control system.

Cedarstone’s Approach to Custom Blending Systems

Cedarstone Industry’s commitment to quality and customer satisfaction is evident in their design and manufacturing process. They utilize high-quality materials, such as stainless steel, to ensure durability and hygiene. Their systems are designed for easy cleaning and maintenance, minimizing downtime and maximizing productivity.

According to customer reviews, Cedarstone provides:

- Good Prices: Cedarstone offers cost-effective solutions without compromising quality.

- Good Order Execution: Cedarstone ensures a smooth and efficient ordering process.

- Good Product: Cedarstone delivers high-quality blending systems that meet customer expectations.

One customer, Richard Cornatzer, highlighted the flawless transaction, accurate product description, quick shipping, and affordable price. Another customer, Ryan Gott, praised the company’s ease of use and lack of delays.

Industries Served

Cedarstone’s custom blending systems are used in a wide range of industries, including:

- Food and Beverage: Creating consistent flavors and textures in sauces, dressings, beverages, and more.

- Pharmaceutical: Precise mixing of active ingredients and excipients for drug formulations.

- Cosmetics: Blending creams, lotions, and other personal care products.

- Chemical: Mixing various chemicals to produce adhesives, coatings, and other products.

The Cedarstone Advantage

Choosing Cedarstone Industry for your blending needs means partnering with a company that is dedicated to providing:

- Expertise: A team of experienced engineers and technicians who understand the complexities of blending processes.

- Customization: Solutions tailored to your specific needs, ensuring optimal performance.

- Quality: High-quality materials and construction for long-lasting durability.

- Support: Excellent customer service and technical support.

A custom-built blending system from Cedarstone Industry is an investment in quality, consistency, and efficiency. By partnering with Cedarstone, businesses can achieve perfect mixing, reduce waste, and improve their bottom line.